PROCESS MAPPING AND MODELING

Summary

When you need a common and documented image that clarifies your complex flows and processes. The results can be used as is or as a basis for continued work on process improvements or the introduction of system support.

Mapping and modeling the many times complex material flows and work processes brings many positive and valuable effects to an organization, for example:

- A good and clear basis to assume continued work on process development and improvement.

- A common picture that reduces misunderstandings and the risk of processes being performed incorrectly.

- Better skills and understanding of the whole, as well as employees' work and situation.

- New employees can quickly understand and learn the business.

- Facilitates communication, easier to show and explain to employees and other stakeholders how a particular process works.

- Good to be able to go back to refresh the memory for processes that are performed very rarely.

Description

Many times, Sim Logistics performs this service as part of a larger project, e.g. during the pre-study, but of course, the service can also be ordered and performed separately.

It is also common for us to model processes for our own sake when carrying out customer assignments. It is a great way to get a clear picture of a customer's material flow and processes in a structured way. It is also very good to be able to go back to models when memory fails or in subsequent follow-up projects.

Performance

The work of mapping and modeling processes often means switching between visits to the business with interviews that provide understanding of the process (mapping) and workshops under which the modeling itself takes place.

Selected personnel performing or in any way affected by the respective process participate in mapping and workshops. If different perceptions exist, participants must discuss, explain to each other and agree on how the process really works. In this way "aha experiences" often happen, lessons are drawn and finally a common picture is created that all participants can feel involved in.

Tool

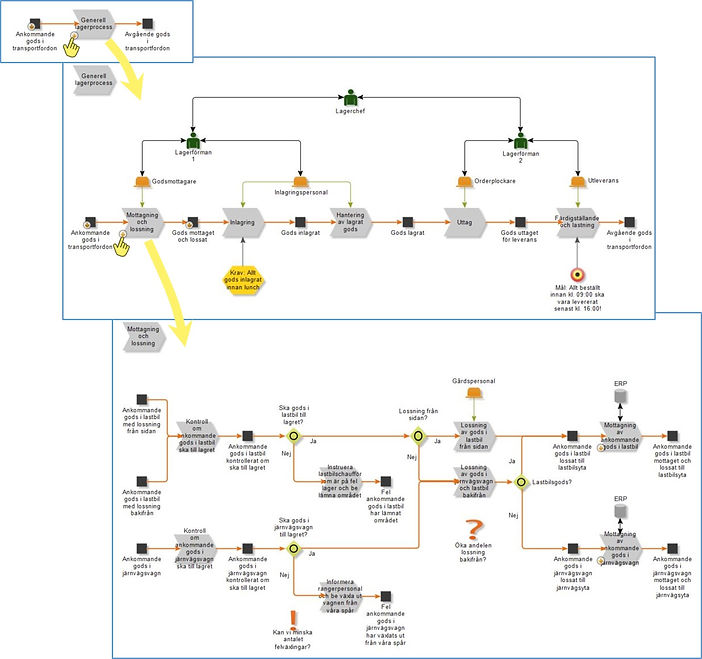

Sim Logistics uses 2C8 from 2Conciliate which is a modern and easy-to-use modeling tool. 2C8 is database-based, which means, if an object changes, the change affect all processes where the object is included, which is smooth and saves time. Processes are degradable in any number of steps to the desired level of detail and are easily accessed via mouse clicks in the model or by tree structure, see image below.

Responsibilities for main and sub processes can be clarified by setting roles and positions. Based on customer needs, different types of models can be created and linked to each other, such as process, simulation, organization, product and stakeholder model.

Results

During the work of mapping and modeling material flows and processes, "peculiarities" often come up to the surface. Unnecessarily difficult working methods or unnecessary process steps are clarified in the visual process model that is created. It is then be easier to see how the process could be improved, resulting in improvement suggestions in addition to a very clear picture of the current process.

For its documentation, of course, the customer receives the models exported to Microsoft Excel and Word format, as well as in clickable HTML format for browser / intranet.

Would you like to discuss a suitable setup for your company

or have more information:

Call +46 761 618384 or email info@simlogistics.se.